Battling COVID-19 With Additive Manufacturing: The Ideation

Amidst the havoc created by the recent pandemic, additive manufacturing companies have openly extended their wish to support the production of essential medical equipment. With an exponential increase in COVID-19 positive cases, 3D printing companies believe that this is the right time to step up and fill the demand-supply gap for necessary equipment. That is to say, additive manufacturing, by all means, has geared up to address global issues that are otherwise difficult to solve with conventional methods. Here’s how the global additive manufacturing forum is preparing the ecosystem in addressing COVID-19. Take a look!

Tooling & Rapid Prototyping

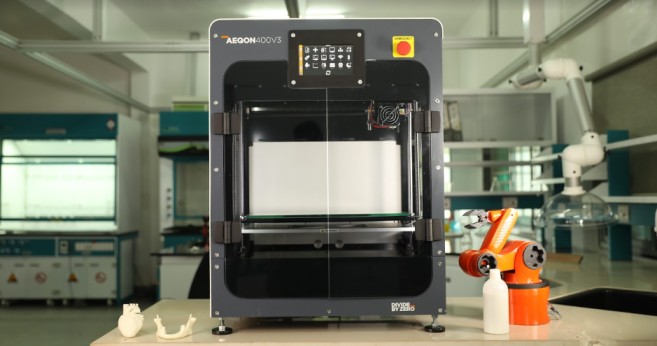

You must be aware of the fact that traditional metal tools can take weeks or sometimes months to manufacture. Although they are suitable for mass production and have a higher lifespan, the need of the hour is rapid manufacturing and quicker delivery of finished products. Consequently, additive manufacturing can act as a bridge between the two. That is to say, 3D printed tools and molds have a greater turnaround time and take just hours instead of weeks to produce. Do you know that 3D printing can help you in rapid prototyping as well as functional tooling at one-tenth of the cost incurred with conventional methods?

3D Printing In Addressing Face

Face Mask Pressure Reliever

Countless numbers of doctors across the world are now facing serious challenges by coming in direct contact with COVID-19 patients. Consequently, the frontline defense system that they have in protecting themselves from airborne contamination is the face mask. However, threaded face masks are causing burns, red marks, wounds, and swells around the ear and nose. Thanks to additive manufacturing, the newly built face adjustable pressure reliever caters to all the drawbacks of traditional face masks that we have been using till date.

3D Printed Respiratory Valves For Corona Virus Treatment

In serious cases of corona virus treatments, patients need to be supplied with a respirator device to help them breathe. The shortage of respiratory devices across the globe is now a serious concern which results in incredible pressure on the country’s healthcare system. Thanks to additive manufacturing, a group of volunteers has now managed to 3D print respiratory valves at a bare minimum cost of just $1.

3D Printed Bag Valve Mask – Emergency Ventilation System

The widespread expansion of Corona Virus has lead to a serious shortage of essential medical equipment such as respirators and face masks. Thanks to additive manufacturing, Leitat has managed to design a 3D printed field respirator that allows healthcare facilities to make use of this essential element during emergencies. It is a mechanical BVM/bagger, not a proper ventilator which has an integrated motor that helps patients with difficulties in breathing. The device is a field respirator in which design and components have been simplified as much as possible to develop a robust, useful and less complex medical device, facilitating both production and assembly.

Hands-Free 3D Printed Door Openers

Did you know that door handles are one of the most infected and contagious objects in houses, hospitals, public transport, and many more? Thanks to additive manufacturing, designers can print hands-free door openers reducing the risk of germs exposure. Research has proved that these door openers don’t require much of drilling or replacing doorknobs. Installing these openers is super easy; all you have to do is fasten two 3D printed pieces together with screws over the door handle.

3D Printed Circuit Splitter and Flow Restriction Devices

With the World Health Organization yet to figure out any effective antidote against corona virus, hospitals across the globe are running out of essential medical equipment such as ventilators. Thanks to additive manufacturing, technologists have managed to devise a 3D printed circuit splitter that enables doctors to ventilate multiple patients with the one anesthesia machine or intensive care unit ventilator.

3D Printed Face Shields

Thanks to additive manufacturing, doctors can better treat corona virus affected patients with better safety and comfort. This face shield enables healthcare workers to better intubate a patient while shielding themselves from contagious germs that could be released from a patient’s respiratory pathway. Apart from healthcare workers, it can be of enormous use to the general public while traveling in and around busy places such as grocery markets. In addition, unlike threaded masks, it doesn’t pose challenges such as burns, wounds and red marks. Read More.

Conclusion

The need of the hour is speed, rapid delivery and faster response to meet the demand. Can you correlate this to additive manufacturing? Don’t you feel these are the exact promises that the 3D printing ecosystem was supposed to function on? Currently, we are facing a situation that is far superior to our technological achievements. But we have the right resources to tackle the situation and bring back life to normal.

We are India’s first 3D printer manufacturing company and the only organization to hold two technological patents in the country. In this challenging time, we are committed to the welfare of our society. That being said, how about you and we work together in achieving a better and healthier ecosystem? Write to us NOW!