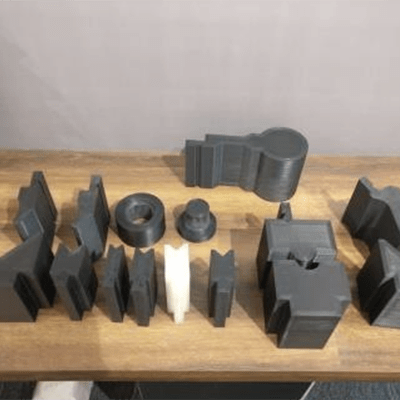

Bend metal parts with plastic? Have you ever come across an idea like this before? Well, Divide By Zero Technologies with its years of research and expertise brings to you one of India’s jaw-dropping innovation in sheet metal forming, Bend Metal Parts With Plastic. Yes, that’s exactly what we’re proposing.

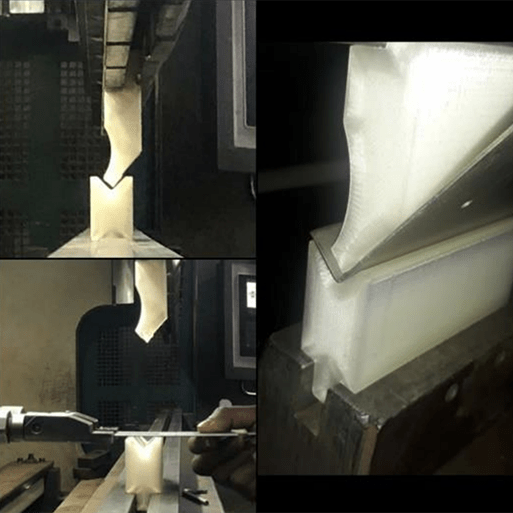

Before we proceed with the large scale advantages of its applications, let us have a quick overview of what press brakes tools are actually meant for. Press Brakes are used to bend sheet metals in a predetermined shape by clamping the work piece between a matching punch and die.

Let’s not bore you anymore with definitions and take you right where we want you to be. Did you know that 3D printed press brake tools will save you over 60-80% of your production time and cost? Yes, that is exactly what Divide By Zero has brought in your domain of business.