AFPM

AFPM - Latest in high speed affordable 3D printing technology for small batch manufacturing

Slow speed 3D printing has been the major cause of delayed prototyping and longer lead time. It is the primary driving force behind losing out on countless purchase orders. Printing at speed over and above 100gm/hr is now a reality.

High-speed 3D printing is the new norm of the advanced, efficient, and productive manufacturing sector. From prototyping to small-batch to high-strength end-use and functional parts, high-speed 3D printing is penetrating the heart of manufacturing and new product development.

Current Challenges

FFF 3D printers generally work on the principle of uniform extrusion rate throughout the print time. The flow of the molten material is constant across the geometry of the part, regardless of the design demands. The biggest disadvantage we have been witnessing is that the filament weight, during the extrusion, decreases significantly at high speed, giving a bad quality finished product.

After 10000+ hours of extensive research, we found that the problem is not in the extruder but lies with the gear and hot-end system.

At high-speed 3D printing, the filament deforms in the gear system. Because of the backpressure generated by the hot-end coupled with no auto-control of the material flow rate, 3D printers show a slight slip in the system leading to a complete or partial nozzle blockage. This results in longer turnaround time in prototyping, small batch 3D printed end use and functional parts.

How does AFPM work?

This patented technology by Divide By Zero relies heavily on intuitive automation and smart software application to automatically determine potential pitfalls, take corrective measures, and minutely calibrate the extruder to optimize the movement and flow to deliver an output quality far superior to all other FDM and FFF 3D printers currently available in the segment.

In simple words, AFPM works on automatic control of material flow rate on a layer by layer basis depending upon part geometry.

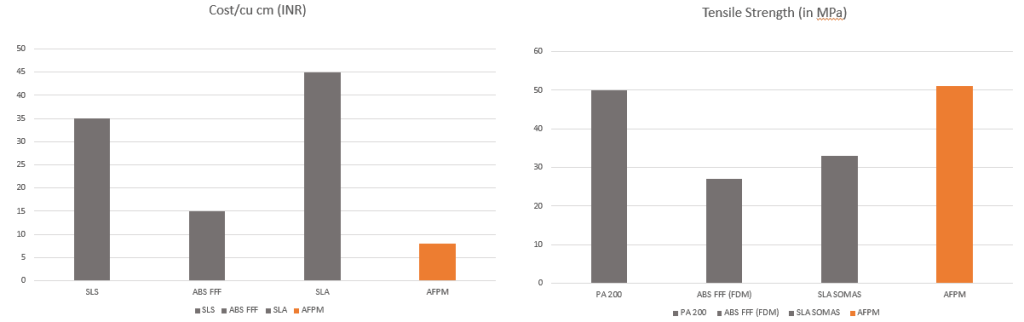

Material Strength

Achieve unmatched deposition rates at high-speed print operations by boosting part strength and quality.

In addition, AFPM matches the industrial standardized metrics of the built materials by complying with the thermal, elasticity, and RA value requirements.

Benefits of AFPM

Adaptive flow rate & Temperature Control

AFPM technology auto adjusts the material flow rates at every odd and even layers of the built component, based on its geometrical stress requirements.

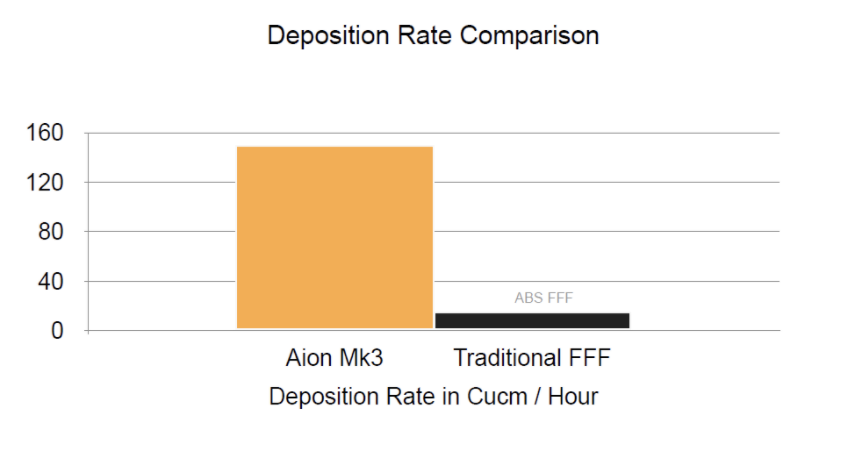

Deposition rate

AI based neural learning ensures adaptive deposition rate as per the geometry. Layers with highly complex organic structures have low deposition rates and those, without details and simple structures, are developed at almost 10X times faster deposition rates.

How AFPM is single handedly challenging small batch CNC machining and traditional FFF 3D printers simultaneously

| CNC Machining | Traditional FFF Printer | AFPM - AION500 MK3 | |

|---|---|---|---|

| Polymer Weight | 110 gm (extra 300 gm required as it is subtractive manufacturing) | 110 gm | 110 gm |

| Print/Machining Time | 12 hrs | 6-7 hrs | 1 hr |

| Raw Material Cost | 11 Rs/gm | 2 Rs/gm | 2 Rs/gm |

| Operating Electricity | 8 KWh or more | 1.5 KWh | 1.5 KWh |

| Operating Electricity Cost | 40 Rs/hr or more | 7.5 Rs/hr | 7.5 Rs/hr |

| Tool Cost | 30000 Rs/year or more | May or may not required (1000-4000 Rs/year) | May or may not required (1000-4000 Rs/year) |

| Labor Cost | 500 Rs/day | May not be required | May not be required |

| Tool | Required | Not required | Not required |

| Tool cost for this part | 2190 Rs | 765 Rs | 727 Rs |

| Tool cost (350 gm/day) | 15,90,000 Rs | 4,40,000 Rs | 4,40,000 Rs |

| Design Limitation | Highly design limited process | No limitation | No limitation |

Achievements - Incorporating AFPM

- Save up to 90% of the time when it comes to traditional CNC machining and up to 85% of the time compared to a market-ready FFF 3D printer.

- Reduce tooling cost and operating overhead costs significantly achieving results quicker and faster.

- More time for innovation without following up with vendors and not being subjected to large MOQ purchase orders.

- Market products 10X faster achieving rising exponential profits annually.

- Reduce customer conversion cycle time by 10 fold with faster product prototyping.

- Low volume production is the new key. On-board your business with mass customization using high-speed 3D printing and unleash your crazy ideas into practical innovation.

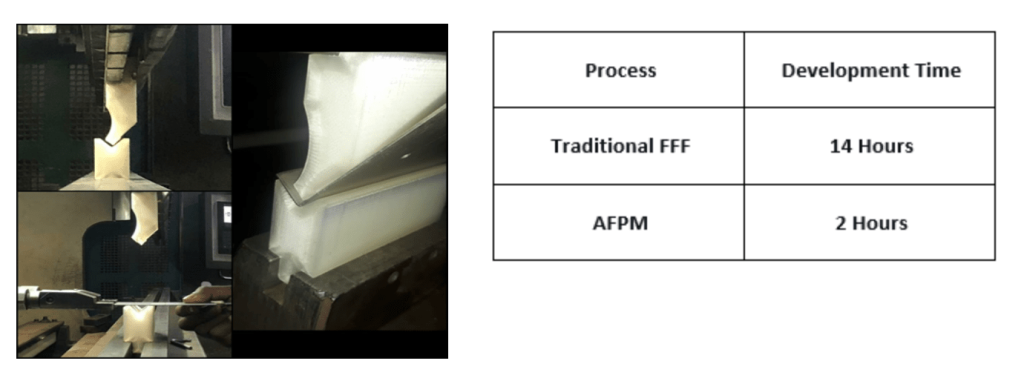

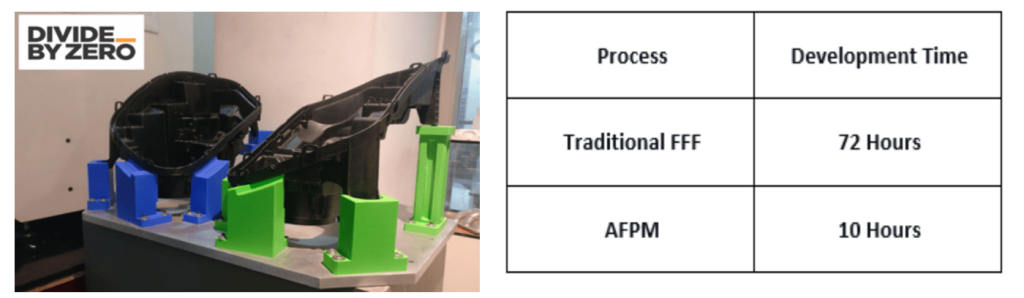

AFPM - Jigs & Fixtures

Jigs & Fixtures are considered as the backbone of any production unit. Jigs & Fixtures are usually manufactured and fabricated using metal or wood imposing serious design challenges and heavy investment in production time.

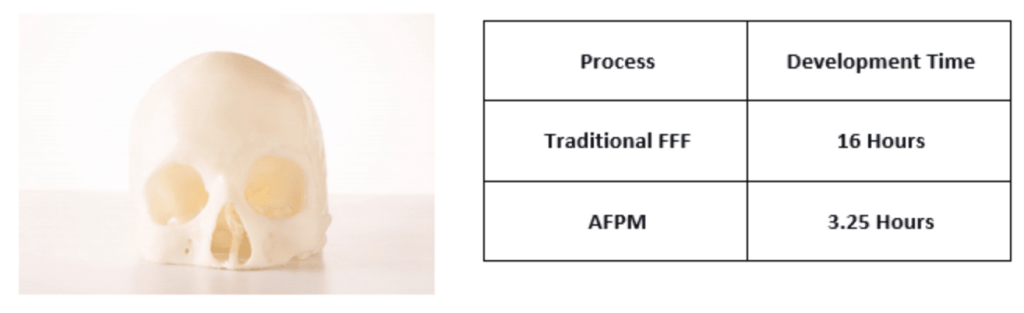

AFPM - Medical Industry

3D printing technology provides countless medical experts with a physical 3D model of the desired patient anatomy that could be used to accurately plan the surgical approach along with cross-sectional imaging.

AFPM - Jigs & Fixtures

3D printing technology provides countless medical experts with a physical 3D model of the desired patient anatomy that could be used to accurately plan the surgical approach along with cross-sectional imaging.

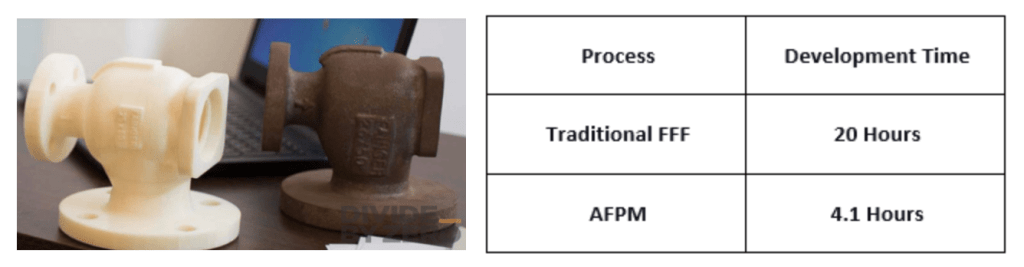

AFPM - Sheet Metal Industry

On-board your business with ground breaking innovations in the 3D printing industry. Now bend metals with plastic using patented AFPM technology. AFPM is fully capable of delivering complex-forming high-strength tools that allow you to bend mild steel, stainless steel, copper with up to 2.5 mm thickness.