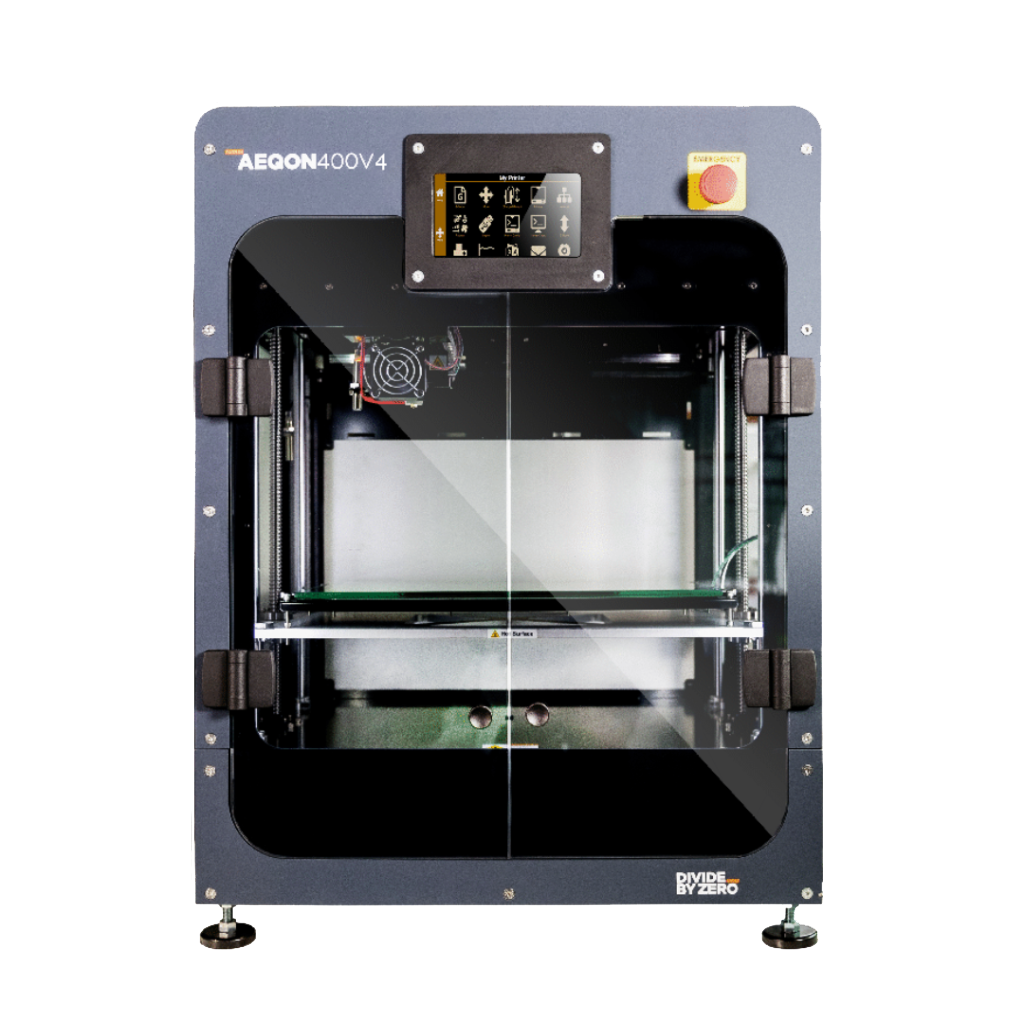

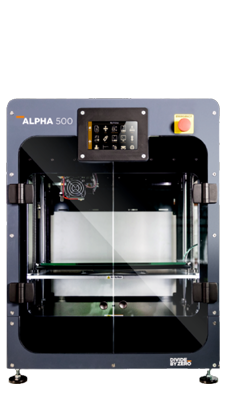

Aeqon 400 V4

India’s First Mid Size Single Extruder 3D Printer with a unique Gantry Design

India’s first mid-size single extruder 3D printer with a unique gantry design for easy 3D printing!

The Aeqon 400 V4 is a low-noise operating, quick-load functionality enabled 3D Printer, with a super-fast slicer software and an industrial-grade build quality which ensures reliable print-cycles. With specially designed high precision ball screws gantry with print speeds of up to 200 mm/sec, this mid-sized 3D printer delivers unmatched precision and repeatability – a prerequisite in rapid prototyping and low-volume batch manufacturing.

Aeqon 400 V4 Features

Future Proof

Machine that grows with you. We call it “Start Small, Think Big” technology. One machine or multiple machines, all AEQON 400V4 machines can be connected through WI-Fi, Ethernet and USB and can be accessed through web browseron your desktop with access to live camera feed of the print and queue your next prints for your operator who has limited machine access if you want it.

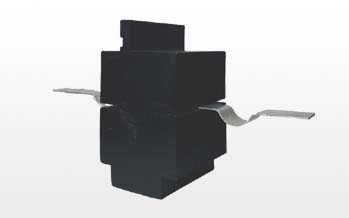

Fast - 2X Deposition Rate

Our advanced extruder design ensures minimum heat creep in the mechanism thanks to our unibody machined extruder that enables you to print with 2x deposition rates. Active filament sensor provides alert upon material flow interruption filament consumption, thus saving valuable time and material, ensuring uniform flow during part build.

35% - Small Footprints

Save upto 35% space with unique design that lets you enjoy similar build platform with huge saving on machine foot prints.

High speed Z axis - dual ball screw

Our development team has come up with unique dual pre – loaded ball screw mechanism in Z axis to ensure vibration free high precision, high speed operation of the machine. It achieves 25% to 40% better speed without compromising on quality contrary to traditional cantilever gantry mechanism.

Versatile - multiple material on one machine

Print materials like carbon fibre, ABS, Polycarbonate, Polyurethane on the same machine. Thanks to our advanced extruder mechanism design that can handle various abrasive materials, variable flow and temperature. You can print flexible, high strength, temperature resistant materials in the same machine with almost zero setup time.

Automatic multi point bed leveling correction

This feature improves the quality of printing and component bed adhesion by taking several measurements of the build platform surface and then adjusting all movement to follow the tilt or contours of the bed & along with unique ability to compensate for all the build surface height irregularities.

Industrial grade 3D printer - Aeqon 400 V4 Product Output

The Aeqon 400 V4 works with 280+ materials including the following:

ABS

Surface Finishing

Cost

Support Removal Control

After Print Accuracy

PLA

Warpage Control

Part Strength

Surface Finishing

Part Flexibility

PETG

Weather-proof

Good chemical

Heat resistance

High impact strength even at low temperature

CF

Part Strength

Warpage Control

After Print Accuracy

Part Shrinkage Control-Small parts less than 100mm

PP

food grade

Medical grade application

Easy to print

Accuracy

TPU

Part Flexibility

Surface Finishing

After Print Accuracy

Part Shrinkage Control-Small parts less than 100mm

HIPS

Part Strength

Warpage Control

After Print Accuracy

Part Shrinkage Control-Small parts less than 100mm

ASA

food grade

Medical grade application

Easy to print

Accuracy

Wood fill

Part Flexibility

Surface Finishing

After Print Accuracy

Part Shrinkage Control-Small parts less than 100mm

PLA-CF

Part Strength

Warpage Control

After Print Accuracy

Part Shrinkage Control-Small parts less than 100mm

Aeqon 400 V4 specifications

Physical Dimensions

NOZZLE Diameter

0.4mm – 0.8mm ( optional )

Extruder

Single ( upgradeable to dual )

Noise Level

<55 dB

Printing Speed

200mm/s Variable as per material profile)

Max Extruder Temperature

305°C

Dimensions

L- 730mm X W- 670mm X H- 900mm

Connectivity

USB, Wi-FI, Ethernet

Accuracy

80-250 Micron

Input Power

220V – 4A – 50Hz

Build Material

ABS+, PLA, Metal fill, Carbon fibre, Polycarbonate, Polyurethane, ABS – PC.

Physical Dimensions

Build Size

400mm*300mm*300mm

Total Machine Weight

113 Kg

Compare

300mmx250mmx200mm

400mmx300mmx300mm

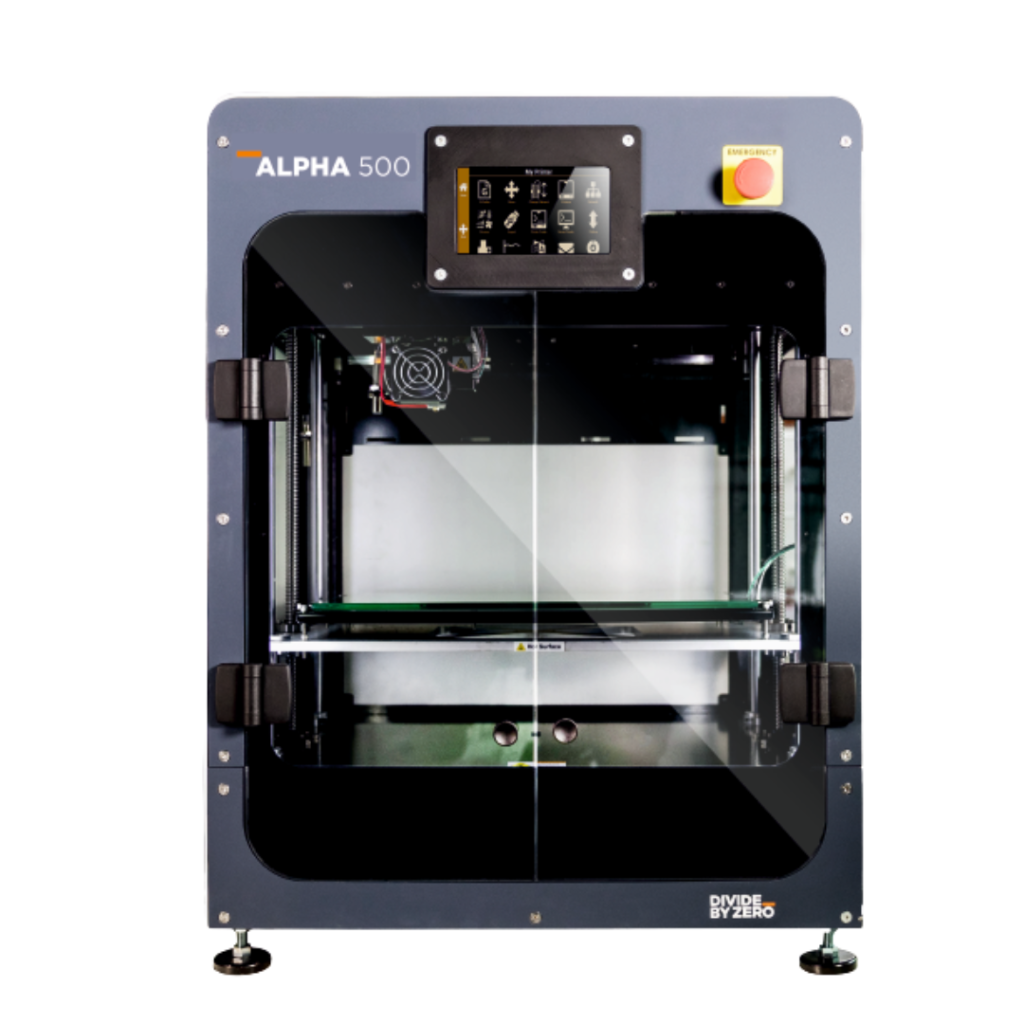

500mmx500mmx500mm

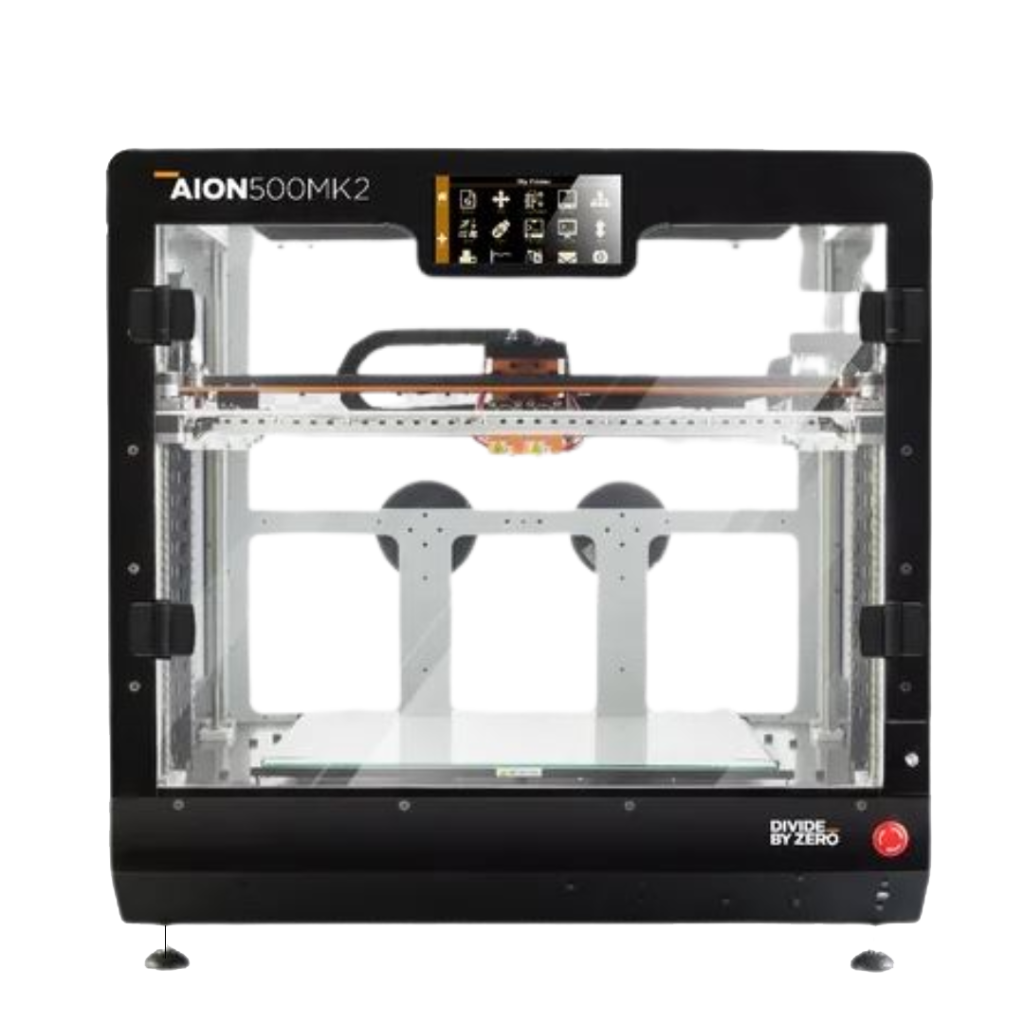

500mmx500mmx500mm

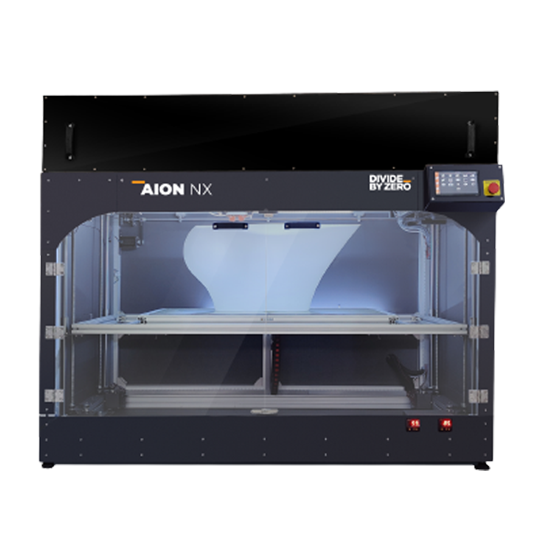

1000mmx1000mmx1000mm

upto 270C

upto 300C

upto 300C

upto 450C

upto 450C

Accucraft Standerd Extruders

Aeqon Standerd Extruders

Single Direct Drive All metal extruder

Dual Drive Liquied Cool Extruder

Dual Drive Liquied Cool Extruder

PLA,ABS, PET,TPU etc

PLA,ABS,HIPS,PC,,PET,TPU , Nylon, CF etc

PLA, ABS, PETG,TPU, CF

ABS, PLA, HIPS, PET, PC-ABS,PC,TPU,AFPM Special,Nylon,AFPM Carbon Fibre, ASA, ABS+

PLA,ABS, PET,TPU etc

X

✔

✔

✔

✔

Manual

Automatic

Automatic

Automatic

Automatic

X

X

X

✔

✔

X

X

X

✔

✔

Other Products