Accucraft i250D

Hybrid Dual Extruder Industrial Grade 3D Printer

Accucraft i250D Features

Professional 3D printing out-of-the-box

Divide By Zero has meticulously pre-assembled, calibrated and tested the Accucraft i250D to deliver professional-grade 3D printing right out-of-the-box. This industrial grade 3D printer is built for accuracy, reliability and affordability in the production process with a strict focus on precision and durability. With the Accucraft i250D, the complex 3D printer assembly process are a thing of the past. With Accucraft i250D, get world-class 3D printing right out of the box.

Dual direct drive extruder

Divide By Zero’s Accucraft i250D industrial grade 3D printer features high-quality all metal direct drive dual extruder mechanism that gives the users freedom of printing two different types or two different colours of the same materials simultaneously.

Unmatched precision and reliability

The Accucraft i250D incorporates premium-grade HIWIN precision series linear guides along with a specially designed XY gantry that delivers positional precision of 16 microns and print speeds up to 200mm/sec. The machine easily delivers an overall print accuracy of ±80-150 microns and has delivered an accuracy of ±50 microns in ideal test environments.

Hassle-free semi - auto bed levelling

The Accucraft i250D features a 4-point semi-automatic bed levelling that takes less than a minute to get ready for the next print batch, making sure that you get repeatability and reprints of consistent quality and make. With the Accucraft i250D, get assured increase in productivity and save precious time in the fast-paced verticals of prototyping and production environments.

High endurance and rigid enclosed body design

The Accucraft i250D by Divide By Zero is housed in a high endurance and robust sheet metal body that maintains stable chamber temperature for controlled heat dissipation delivering seamless adhesion and uniform print consistency.

Prints with soluble support

As the Accucraft i250D is a dual extruder 3D Printer, one extruder prints the intended material while the other prints the support material. These support materials can easily be removed by dissolving it an organic solvent, making the post processing hassle free and easy with no manual intervention

Multi-material compatibility

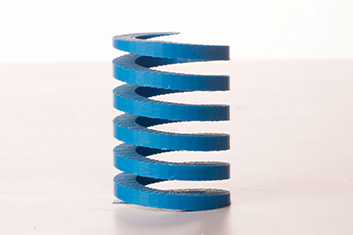

The Accucraft i250D offers easy compatibility with a wide range of industry-standard 3D printing materials material such as ABS, PLA, HIPS, PETG, Wood-infill, Metafill, Carbon Fiber, Polycarbonate and flexible Filaments among a list of others.

Value for money

Despite being an industrial-grade 3D printer, the Accucraft i250D is cost-effective and has a low running cost of Rs. 4/gm thereby offering tremendous value for money and return on investments.

Zero clogging filament tracker

Divide By Zero has incorporated a fast response filament sensor that continuously monitors and actively repairs extruder clogging, thereby ensuring zero failed prints and a high level of reliability in fast-paced prototyping and production environments.

Multiple connectivity options

This compact yet powerful 3D printer can be connected via USB, SD Card, Ethernet and Wi-Fi. This allows users to get secure access to the machine’s control software, along with multi-user support

Remote print monitoring system

The Accucraft i250D features a built-in camera with internet connectivity (via Ethernet or Wi-Fi) to allow users to remotely monitor print queues easily giving them full visibility of the entire print process.

Support and warranty

Divide By Zero ensures that all its products are manufactured and tested while strictly adhering to the highest international quality standards in order to deliver industrial-grade 3D printing solutions to its customers. Our products come with a one year warranty and 2 days intensive product training along with unmatched after-sales support and technical assistance.

Industrial grade 3D printer - ACCUCRAFT I250+ Product Output

The Accucraft i250D works with 280+ materials including the following:

ABS

Surface Finishing

Cost

Support Removal Control

After Print Accuracy

PLA

Warpage Control

Part Strength

Surface Finishing

Part Flexibility

PETG

Weather-proof

Good chemical

Heat resistance

High impact strength even at low temperature

Accucraft i250D specifications

Physical Dimensions

Filament- Diameter

1.75mm

Extruder- Diameter

0.4mm

Extruder- Temperature

upto 270° C

No. of Extruder

2

Model Of Extruders

Direct drive all metal dual Extruders

Recommended Materials

PLA, ABS, HIPS, PET-G, PLA-CARBON FIBRE, Flexible Filaments, etc.

Material Support

Non Hygroscopic HIPS

Print Accuracy

80 – 150 microns

Maximum Print Speed

200mm/sec

Maximum Travel Speed

300mm/sec

Layer Precision

0.1-0.30 mm

Heated Bed

Yes

Bed Temperature

90° C max

LCD Support

Yes

Connectivity

USB, SD card, Wifi

Print Monitoring System

In build camera with Wi-Fi connectivity

Enclosure Type

Complete enclosed chasis, even spool is covered

Power Requirement

110-220VAC, 700 Watt PSU with 1 Year Warranty

Run Time Change Setting Option

Yes

Yes (pause and resume even after extruder movement), Semi-Automatic

Positional accuracy 16 micron using HIWIN High Precision Linear Guide Rails.

Less than 70db

Covered under 2 day free training

Physical Dimensions

Maximum printable area

200mm * 250mm * 200mm

Total Machine Weight

35Kg

Software

Software Supported

Repetier, Cura, Custom Software for DBZ, Kislicer

Warranty

Warranty

1 year

Compare

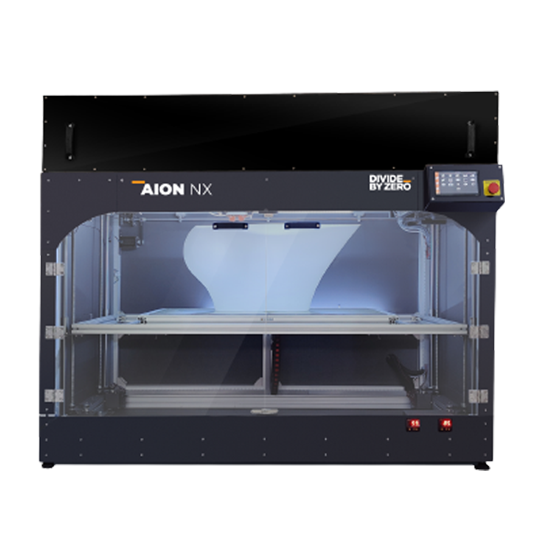

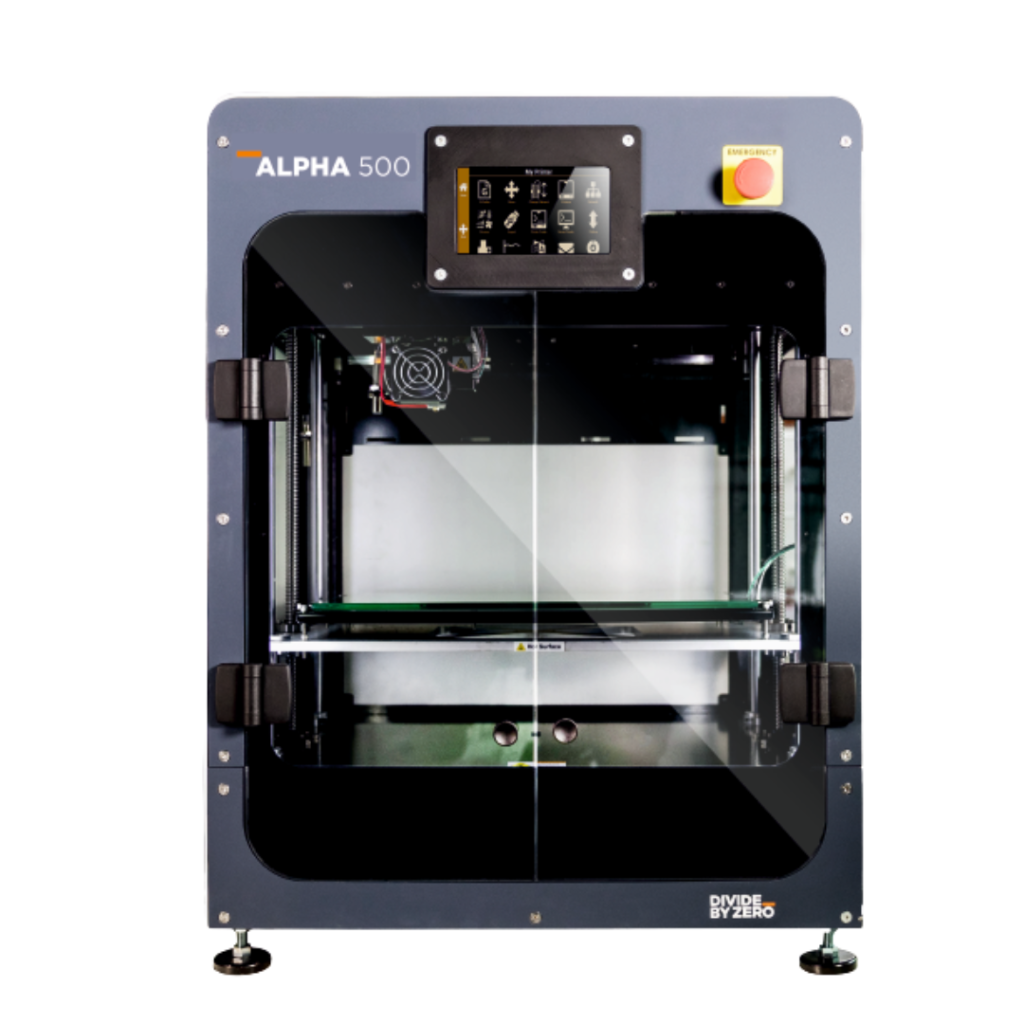

300mmx250mmx200mm

400mmx300mmx300mm

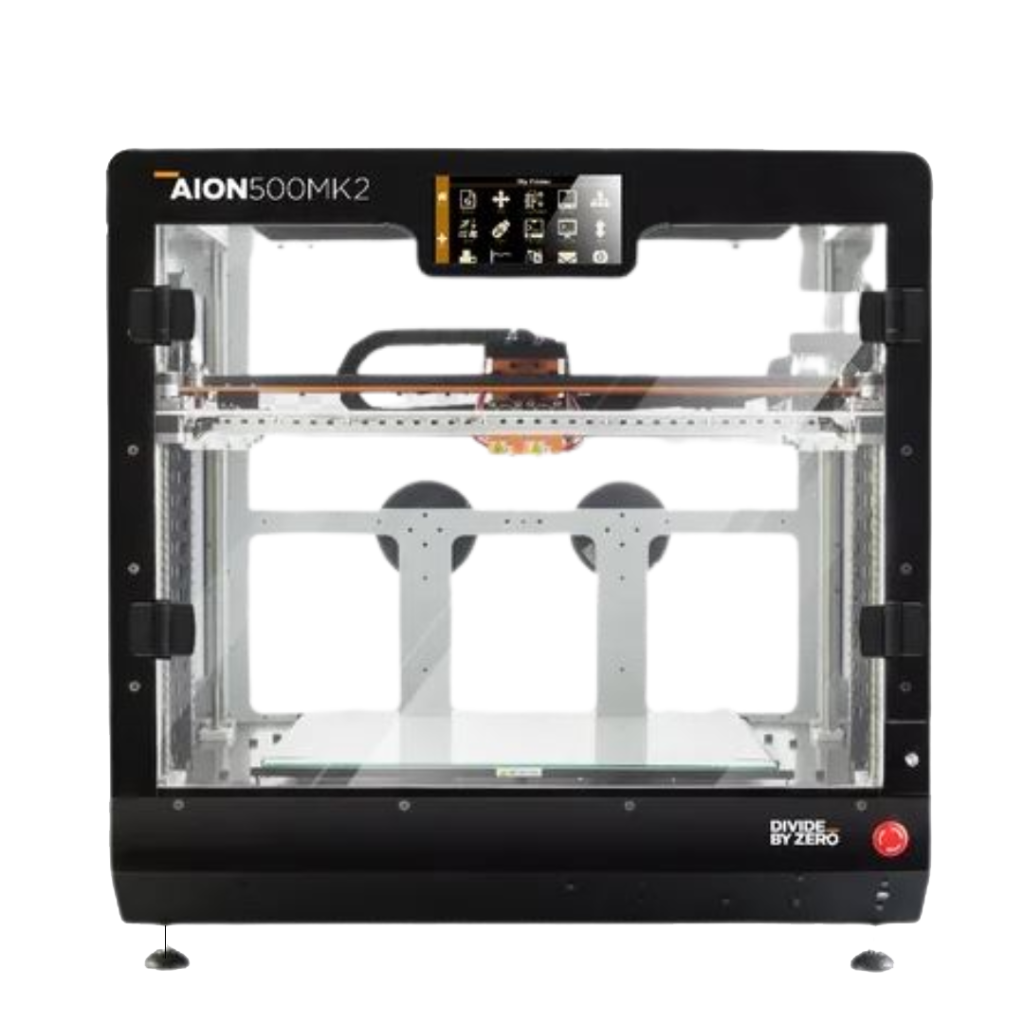

500mmx500mmx500mm

500mmx500mmx500mm

1000mmx1000mmx1000mm

upto 270C

upto 300C

upto 300C

upto 450C

upto 450C

Accucraft Standerd Extruders

Aeqon Standerd Extruders

Single Direct Drive All metal extruder

Dual Drive Liquied Cool Extruder

Dual Drive Liquied Cool Extruder

PLA,ABS, PET,TPU etc

PLA,ABS,HIPS,PC,,PET,TPU , Nylon, CF etc

PLA, ABS, PETG,TPU, CF

ABS, PLA, HIPS, PET, PC-ABS,PC,TPU,AFPM Special,Nylon,AFPM Carbon Fibre, ASA, ABS+

PLA,ABS, PET,TPU etc

X

✔

✔

✔

✔

Manual

Automatic

Automatic

Automatic

Automatic

X

X

X

✔

✔

X

X

X

✔

✔

Other Products

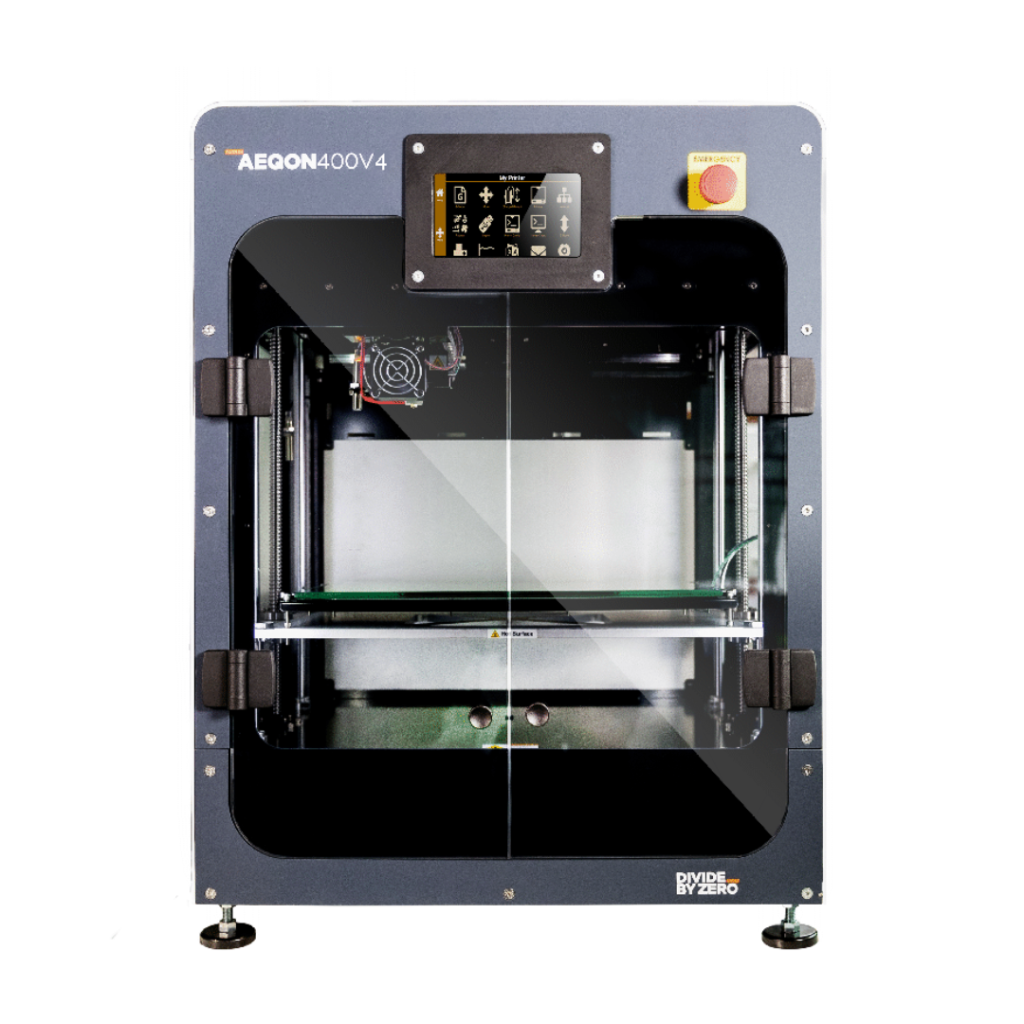

AEQON 400 V4