The realm of 3D printing has witnessed an unprecedented evolution over the past few decades.

From its nascent stages to becoming a cornerstone of modern manufacturing, 3D printing technology has continuously pushed the boundaries of what’s possible. Among the innovations propelling this field forward, servo extruders stand out as a game-changing development. The Rise of Servo Extruders The transition from traditional extrusion methods to servo extruders marks a significant leap in 3D printing technology. Traditional extruders, often relying on stepper motors, have been the standard for controlling the flow of filament in 3D printers.

However, the introduction of servo extruders has set a new standard for precision and efficiency. Servo motors, known for their accuracy and speed control, enable servo extruders to monitor and adjust the filament flow with unmatched precision. Enhancing Precision and Efficiency The impact of servo extruders on 3D printing cannot be overstated. These advanced components offer superior control over the extrusion process, leading to higher quality prints with finer details.

Servo extruders can adjust the filament flow in real-time, compensating for any potential issues that could affect the print quality.

This level of control also translates to increased efficiency, as it reduces the likelihood of print failures and material waste. Real-World

Applications Industries ranging from aerospace to automotive and consumer electronics have already begun to reap the benefits of servo extruders. In aerospace, where precision and reliability are paramount, servo extruders enable the production of complex parts with tight tolerances.

Automotive manufacturers utilize this technology for prototyping and producing durable components quickly and cost-effectively. Meanwhile, in the consumer electronics sector, the ability to produce intricate designs with high accuracy is indispensable.

Conclusion: The Future Outlook of Servo Extruders in 3D Printing

The Future Outlook of Servo Extruders in 3D Printing As 3D printing technology continues to evolve, servo extruders are poised to play a pivotal role in its growth. Their ability to enhance print quality, reduce waste, and improve efficiency addresses many of the challenges previously faced by manufacturers and hobbyists alike. With ongoing advancements in servo technology and its integration into 3D printing systems, the future of manufacturing looks increasingly precise, efficient, and limitless. Servo extruders are not just an incremental improvement; they represent a significant shift towards a future where 3D printing can fulfill its promise of revolutionizing production across industries. As we look ahead, the continued development and adoption of servo extruders will undoubtedly unlock new possibilities, making 3D printing more accessible, reliable, and versatile than ever before. In this transformative era, all Divide By Zero 3D printers are equipped with servo extruders, setting a new benchmark for reliability. This integration makes our machines 5 times more reliable than those without, ensuring that every print is not only of exceptional quality but also consistently dependable. With Divide By Zero’s commitment to pioneering advancements, our 3D printers are at the forefront of bringing the unparalleled benefits of servo extruder technology to a wide array of industries and applications, redefining what’s possible in 3D printing.

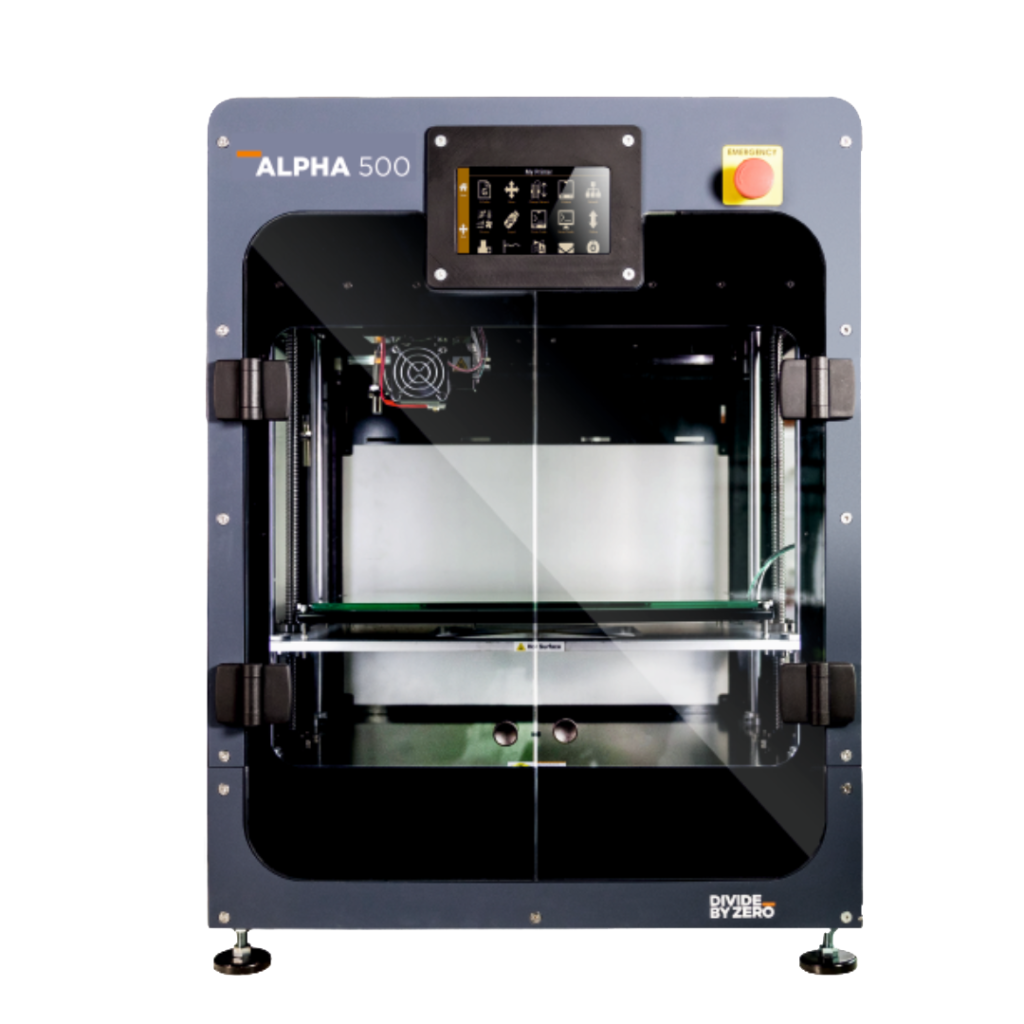

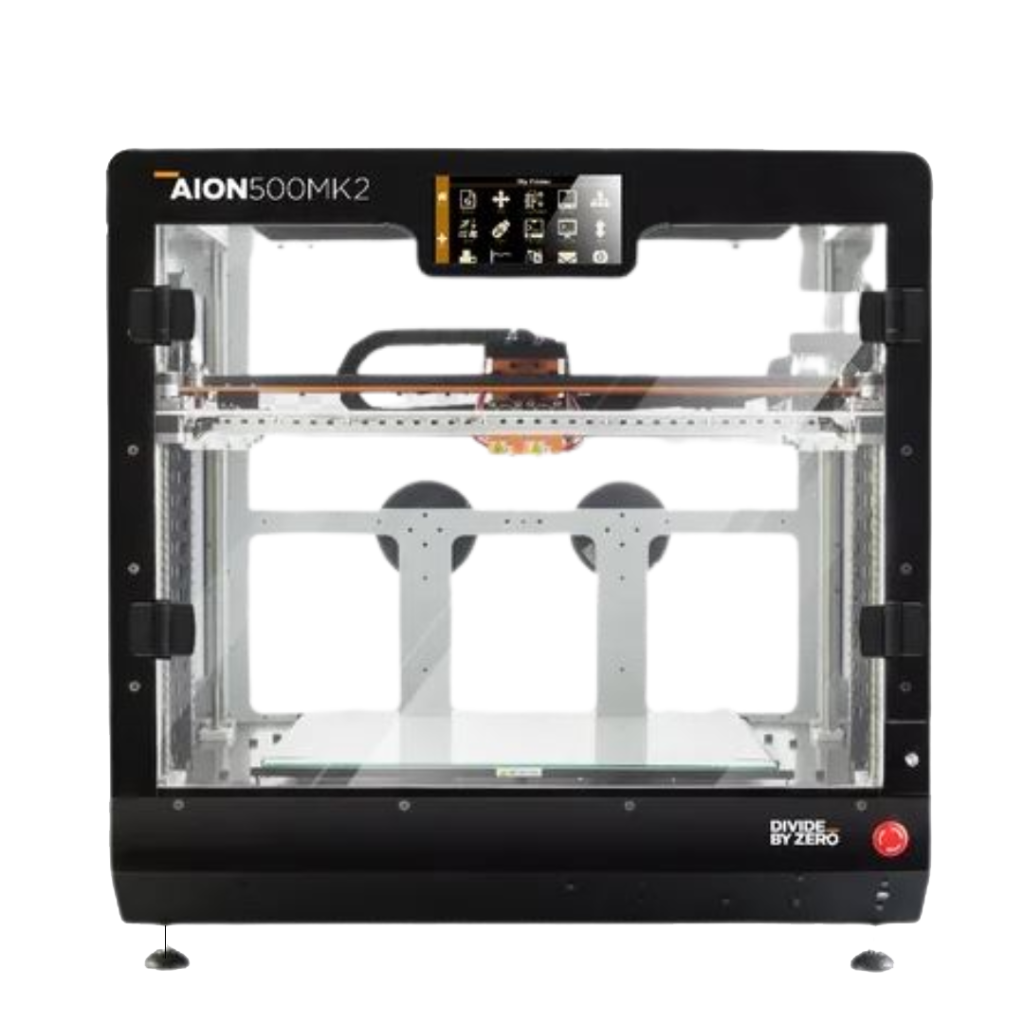

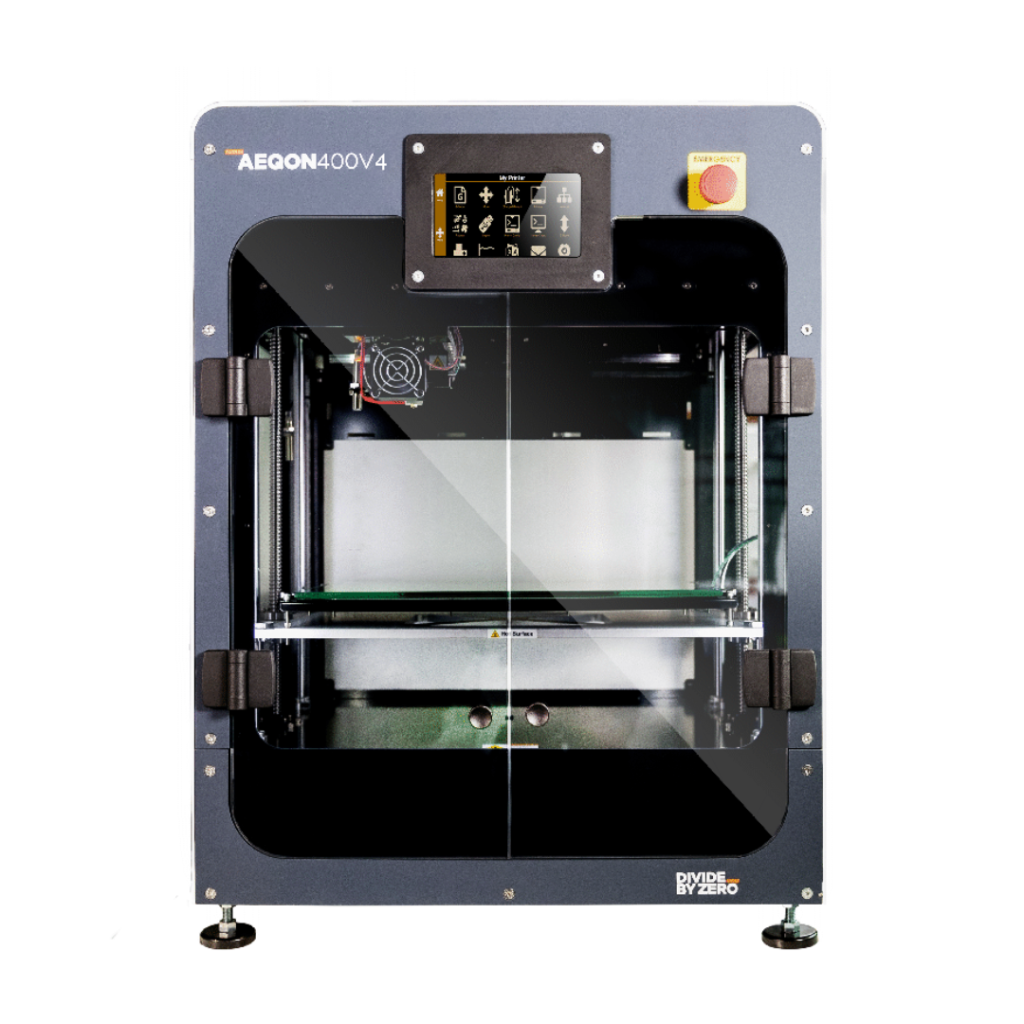

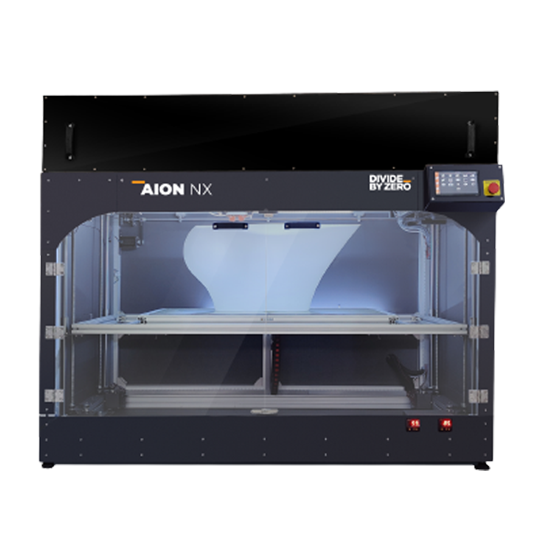

Checkout the DBZ's printers that offer Servo Extruder Functionality

AEQON 400 V4

India’s First Mid Size Single Extruder 3D Printer with a unique Gantry Design

AION NX

Imagine it. PRINT BIG. Customizable

large format 3D Printer delivered

in CKD Kit. Made in India –

Made for the world.