As you must be aware, Jigs & Fixtures are considered as the backbone of any production unit. Having said that, did you know recent advents in additive manufacturing have reduced heavy consumption of key resources such as manpower and cost incurred?

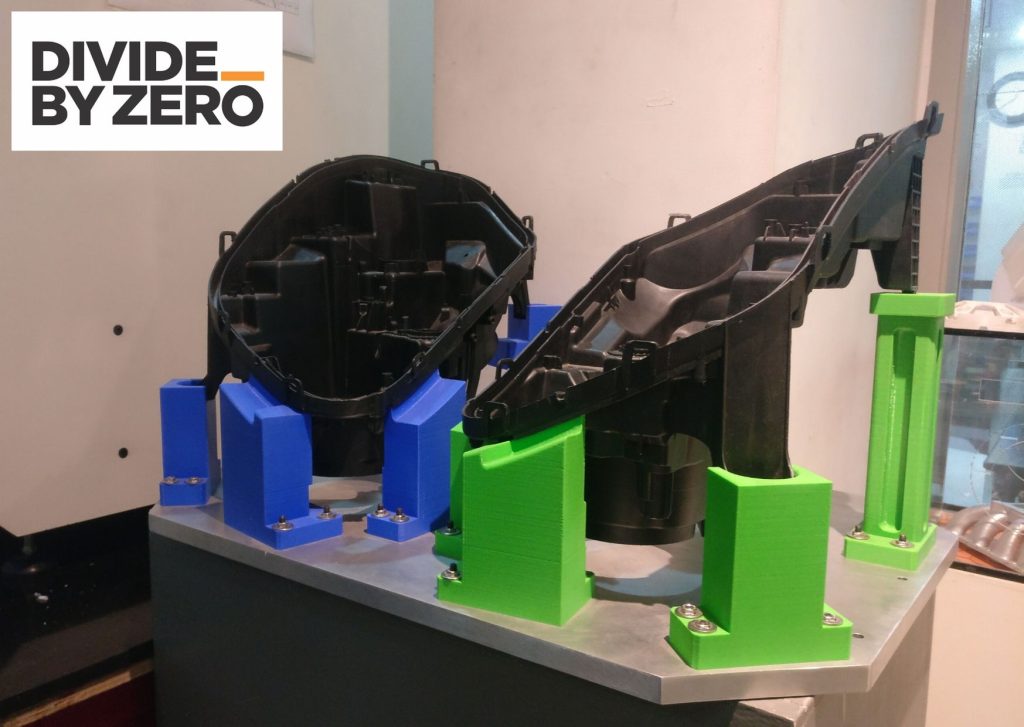

Jigs & Fixtures are usually manufactured and fabricated using metal or wood imposing serious design challenges and heavy investment in production time. Divide By Zero Technologies has come with its patented AFPM technology in additive manufacturing to produce Jigs & Fixtures using 3D printing. AFPM is far superior and reliable 3D Printing technology compared to the conventional FFF and other 3D printing technologies currently available.

Let us now quickly discuss the diverse advantages of 3D printing in applications pertaining to Jigs & Fixtures.

Ergonomics

Conventional designed tools being heavy and unmanageable, exhibiting huge strain to the labor force in tool handling. Moreover, there are times when manufactured tools come out to be flawed units resulting in significant downtime and client discomfort. With 3D printing, vendors can rest assured of the design efficacy of any complexity.

Weight Reduction

Polymer 3D printing has proved to be a better alternative to subtractive manufacturing when it comes to small-batch production? They are light-weight and aids in increased productivity.

Design Complexity

You must be aware that intricate design features require specialized machining and tooling processes when implemented with metal tooling. With 3D printing, you can cut down production costs and machining time, achieving blind internal complex features that are otherwise impossible with any other conventional manufacturing process.

Quick Delivery

Conventional machining usually requires detailed prototype drawings, reviews, and complex design challenges. With additive manufacturing, it’s just a walk in the park for you. All you need to do is to create a design and program it into the machine. The biggest advantage is that the machine will run unattended with minimum to zero operator supervision and will deliver new parts overnight.

Cut Down Cost Incurred

Did you know that 3D printing will cut down 2 major cost-invested domains of your business – material and labor? Yes, that’s right, and 3DP will reduce the same by over 60%. Most importantly, none of your materials used will end up as scraps on the floor. 3D printing can save over 70-80% of the required time as compared to other conventional counterparts.

Here are some of the factors that showcase how 3D printing can help boost your business besides booking profits every single day.

Optimized Design

It gives us the benefit of flexible and optimized designs by starting small and scaling up rapidly. The future design is first prototyped in a miniature form to test multiple aspects and practical functionalities.

Easy Customization

3D printing helps automakers with mass production of customized features, be it interior or exterior, at low cost and in a shorter time-span.

Measurement & Validation

It assures us with the highest standards in quality, measuring, and validating every aspect of the vehicle between simulation and final product.

Optimal use of Raw Materials

3D printing allows lower consumption of materials and wastage which is beneficial for all stages of manufacturing.

It’s not about just saving millions, it’s about getting smarter by thinking big also. How about adapting to new-age technologies and save a considerable amount of business resources? Want to see the magic unfolding?

Let us be the additive manufacturing partner in pursuit of your growth and success.